Band heaters

Check availability

The band heaters are designed for heating by conduction of cylindrical parts. Used in many manufacturing processes such as injection molding, extrusion, molding … or specific application such as tank heating, they are found in many industries as plastics, automotive, chemicals, food …

Manufactured from mica or ceramic insulators, bare shielded circuits or aluminum overmolded, they can also be sealed or equipped with a thermal insulation.

The choice of technology depends the conditions of use such as temperature, power and the environment.

The choice of connections will depend on the implementation of the installation and usage constraints.

The product examples below show a range of options that is not exhaustive. Online technical support allows you to predefine your needs and specifications. Furthermore a wide range of standard products is in stock.

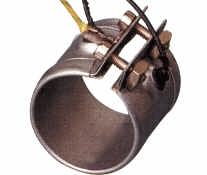

The mica shielded bands

Designed for use up to 450 ° C a specific charge of 6W/cm max ²,

A resistor made of nickel chromium 80/20 which is wound on a mica support and protected by a metallic shield (brass, steel or stainless steel).

Specifications, connections, variations and options are described in « Définition technique pour une demande de prix ou une commande » .

| Collier à fils Voir liste disponible en stock |

Collier à bossages Voir liste disponible en stock |

Collier étanche (de buse) Voir liste disponible en stock |

|

|

|

| Collier à connecteur à broche | Collier à connecteur à fils | Collier avec support de sonde |

|

|

|

Ceramic bands

For applications up to 900 ° C, they work by conduction and rayonnement . Made out of nickel chromium 80/20, or any other suitable resistive material, this resistor is wound and inserted into articulated ceramics. A heat shield between the ceramics and an external metal sheath protect the whole while directing the flow of heat towards the center.

A further adjustment may be made to reduce the surface temperature, prevent any risk of burning and reduce energy consumption.

Specifications, connections, variations and options are described in « Defining a technical inquiry or an order. »

Shield circuit bands

A stainless steel shield component is shaped like a cylinder and held in a metallic clamp. Designed to withstand harsh environments such as vibrations or corrosion. They are produced according to to your specifications.

A stainless steel shield component is shaped like a cylinder and held in a metallic clamp. Designed to withstand harsh environments such as vibrations or corrosion. They are produced according to to your specifications.

Aluminium or bronze overmolded bands

One or more shielded elements are cylinder-shaped or half-shell shaped and then overmolded with aluminum or bronze. For applications in harsh environments requiring high reliability and good distribution of heat. A specific study is carried out in each case.

One or more shielded elements are cylinder-shaped or half-shell shaped and then overmolded with aluminum or bronze. For applications in harsh environments requiring high reliability and good distribution of heat. A specific study is carried out in each case.

Advices

Ensure perfect cleanliness of the part to be heated before installation to avoid any inclusion of material or risk of smoke or fire.

After an initial warm-up, tighten the clamp to ensure proper contact and heat transfer and improve the life of the resistor.